Ford 9 Inch Rebuild / Gear Setup

|

9 Inch Rebuild/Gear Setup |

|

Copyright © 2000 James Oxley, All International Rights Reserved. This document may not be copied or published without prior written consent of the author.

NOTE:

IF YOU ARE A BEGINNER, THIS IS THE REAR YOU WANT TO START WITH. THE 9" FORD REAR IS A MODEL OF SIMPLICITY FOR ADJUSTMENT OF PINION DEPTH AND SETTING BACKLASH

NOTE:

TO PERFORM THIS REBUILD, YOU SHOULD HAVE A SHOP MANUAL THAT LISTS TORQUE SPECS, A FULL SIZE FLOOR JACK , TWO (3 TON MIN) JACK STANDS, A DIAL INDICATOR WITH MAGNETIC/STATIC BASE, A VIERNER CALIPER, GEAR PATTERN GREASE, "RED" GRADE THREAD LOCKER. INCH-LB TORQUE WRENCH, AND 150+ FT-LB TORQUE WRENCH

1. REMOVE WHEELS AND PLACE REAR AXLE ON JACKSTANDS. I LIKE JACKING BETWEEN SHOCK MOUNT AND CENTER SECTION. JACK STANDS SHOULD BE PLACED BETWEEN SETS OF U-BOLTS, DIRECTLY UNDER LEAF SPRINGS.

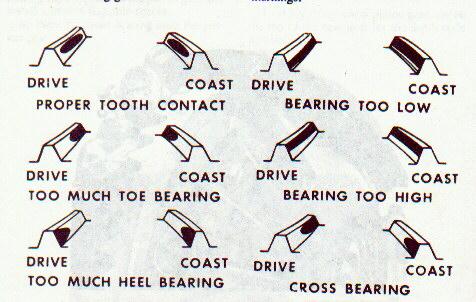

2. RELEASE EMERGENCY BRAKE. REMOVE BRAKE DRUMS.

NOTE:

BACKING OFF ON INTERNAL SHOE ADJUSTING STAR WHEEL (ACCESSED THROUGH HOLE IN BACKING PLATE) AND/OR HITTING BRAKE DRUM WITH HAMMER BETWEEN 2 STUDS IN AXIAL DIRECTION MAY BE NEEDED TO REMOVE STUBBORN DRUMS. WHEN HAMMERING DRUM, KEEP WHEEL NUTS ON STUDS TO AVOID THREAD DAMAGE.

3. ROTATE AXLE TO LINE UP HOLE IN AXLE FLANGE WITH ONE AXLE RETAINING BOLT. REMOVE AXLE RETAINING BOLT. REPEAT THIS 3 MORE TIMES TO REMOVE A TOTAL OF 4 AXLE RETAINING BOLTS. REMOVE AXLE BY PULLING STRAIGHT OUT. AXLE MAY REQUIRE SUBSTANTIAL FORCE TO BE REMOVED. ENSURE SMALL PAN IS UNDER END OF AXLE ASSY TO CATCH ANY LEAKING REAR END FLUID. USE MASKING TAPE TO MARK AXLE AS TO DRIVER OR PASSENGER SIDE.

4. INSPECT AXLE BEARING AND RACE FOR PITTING, CORROSION, OR WEAR. CAREFULLY INSPECT AXLE SEAL FOR MISSING RUBBER. IF RUBBER IS SHOT, NEW SEALS WILL BE NEEDED. REINSTALLING AXLE AND LOCATING MISSING PART OF SEAL ON TOP OF TUBE AND/OR USING GASKET SEALER WILL NOT WORK CORRECTLY. I TRIED THEM BOTH. REPLACING AXLE SEALS MAY REQUIRE NEW BEARINGS (DEPENDING HOW THEY PRESS OFF) AND WILL REQUIRE NEW BEARING RETAINER RING. ENSURE BEARING RACES ARE CHANGED IF NEW BEARINGS ARE INSTALLED.

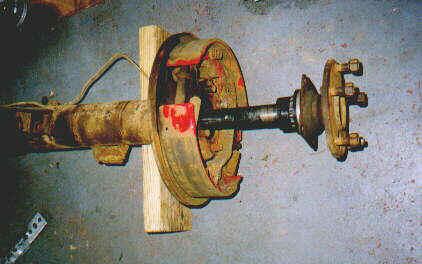

5. REMOVE 10 NUTS FROM 3RD MEMBER ASSEMBLY. REMOVE 10 BRASS WASHERS FROM STUDS TAKING CARE TO NOT DESTROY THEM. BENDING THEM SLIGHTLY TO GET THEM OFF IS OK. PICTURE SHOWS 3RD MEMBER ALL READY OFF STUDS.

6. USING RUBBER HAMMER OR BOTH HANDS, CRACK GASKET, PULLING UPWARD ON 3RD MEMBER ASSY. ENSURE LARGE PAN IS UNDER 3RD MEMBER TO CATCH OIL. SMALL SCREWDRIVER CAN BE PLACED AT BOTTOM BETWEEN 3RD MEMBER AND HOUSING TO ALLOW THOROUGH FLUID DRAINING. DRAIN FOR 1 HOUR MIN TO ENSURE ALL OIL IS OFF 3RD MEMBER.

7. REMOVE 3RD MEMBER. JERKING UP/DOWN AND SIDE/SIDE MOTIONS MAY BE REQUIRED TO GET 3RD MEMBER OUT. SOMETIMES STUDS ARE ANGLED SLIGHTLY, MAKING 3RD MEMBER A TIGHT FIT. PLACE 3RD MEMBER ON CLEAN RAGS/SURFACE. SOP UP REMAINING FLUID IN BOTTOM OF CASE. CHECK FOR HEAVY/LARGE METAL PARTICLES ON CASING BOTTOM.

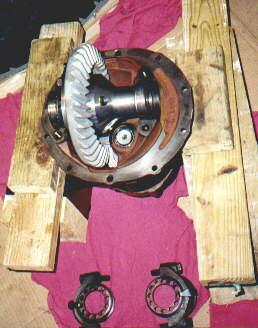

8. SETUP 3RD MEMBER ON BLOCKS AS SHOWN. A 6 X 6 AND 2 -2 X 4’S ON EITHER SIDE WORKS WELL FOR THE CORRECT HEIGHT.

NOTE:

IF THIS IS YOUR FIRST GEAR SETUP/INSTALL, YOU MAY WANT TO PERFORM A REFERENCE CHECK ON BACKLASH AND A PATTERN CHECK ON DRIVE AND COAST. THIS WILL GIVE YOU A GOOD IDEA OF WHAT BACKLASH YOU WILL NEED AND WHAT THE GEAR PATTERNS LOOK LIKE UPON RE-ASSEMBLY. SKIP 9, 10 AND 11 IF YOU ARE SEASONED GEAR INSTALLER.

9. INSTALL DIAL INDICATOR AS SHOWN. MAKE SURE DIAL INDICATOR IS EXTREMELY RIGID, OR RESULTS WILL BE SKEWED. ENSURE DIAL POINTER IS SET SO IT TOUCHES THE TOP OF ONE GEAR TOOTH AND IS TANGENT TO THE OUTER ARC OF RING GEAR TEETH. HOLD PINION FLANGE SOLID AND ROTATE RING GEAR BACK AND FORTH, ENSURING PINION/FLANGE DOES NOT MOVE. PLAY SHOULD BE EVIDENT AND THE AMOUNT OF BACK AND FORTH PLAY IS CALLED BACKLASH. IT SHOULD BE AROUND .008 TO .012 INCHES.

10. PAINT ALL RING GEAR TEETH, BOTH SIDES, WITH GEAR MARKING COMPOUND (USUALLY A WHITE TYPE OF GREASE). PUT FORCE ON RING GEAR IN EITHER DIRECTION (SMALL RUBBER PAD PRESSED AGAINST RING GEAR TEETH WORKS WELL FOR THIS). SPIN PINION/FLANGE BACK AND FORTH, 10 OR 20 TIMES, ENSURING 5 OR 6 RING GEAR TEETH MESH WITH PINION GEAR TEETH. RELEASE FORCE ON RING GEAR AND ROTATE IT TO A POINT WHERE PREVIOUSLY MESHED TEETH (PATTERN IN GREASE) CAN BE SEEN. PATTERN SHOULD LOOK LIKE CORRECT MESH PATTERN IN DIAGRAM BELOW.

11. REPEAT PROCEDURE, FORCING RING GEAR IN OPPOSITE DIRECTION. CHECK PATTERN AGAIN. BOTH PATTERNS SHOULD BE IN CENTER OF TOOTH AND NOT RUNNING OFF THE EDGE OF ANY TEETH. PATTERN CAN BE CHECKED AT VARIOUS LOCATIONS ON RING GEAR TO ENSURE PATTERNS ARE THE SAME OVER ENTIRE RING GEAR. DOING THIS WILL ALSO ENSURE RING GEAR IS SEATED CORRECTLY ON DIFFERENTIAL AND RUNOUT ON RING GEAR IS ACCEPTABLE.

12. REMOVE DIAL INDICATOR IF INSTALLED AND LOOSEN 4 CARRIER BEARING CAP BOLTS. MAKE SURE BEARINGS CAPS ARE MARKED IN SOME WAY SO THEY ARE INSTALLED AS THEY CAME OUT. THEY ARE NOT INTERCHANGEABLE. REMOVE CARRIER BEARING CAPS. REMOVE DIFFERENTIAL/RING GEAR, ENSURING BEARING RACES/THREADED SIDE ADJUSTERS DO NOT FALL ON FLOOR.

13. USING LARGE ADJUSTABLE WRENCH, HOLD PINION FLANGE AND REMOVE PINION NUT. REMOVE 5 BOLTS HOLDING PINION, PINION BEARINGS AND RETAINER TO MAIN CASING.

14. REMOVE PINION ASSEMBLY. CARE SHOULD BE EXERCISED TO PREVENT DAMAGE TO RUBBER O-RING ON PINION ASSEMBLY. ENSURE METAL SHIM(S) BETWEEN MAIN CASING AND PINION RETAINER ARE ACCOUNTED FOR AND NOT DAMAGED. SLIDE PINION OUT OF RETAINER (MAY NEED TO BE PRESSED OUT) AND PRY OFF PINION SEAL ON END OF RETAINER.

15. PRESS OFF AND REPLACE REMAINING PINION BEARING. REPLACE BEARING RACES ON BOTH SIDES OF PINION RETAINER. REINSTALL PINION INTO RETAINER .

16. INSTALL NEW CRUSH COLLAR ON PINION (SEE PICTURE BELOW). INSTALL REMAINING PINION BEARING, PINION FLANGE, AND NEW PINION NUT. HOLDING PINION FLANGE WITH VERY LARGE ADJUSTABLE WRENCH, TORQUE NUT TO 175 FT-LBS. ENSURE ROTATIONAL FORCE OF PINION GEAR DOES NOT EXCEED 5-8 IN-LBS FOR NEW BEARINGS OR 8 IN-LBS FOR USED BEARINGS. IT IS BEST TO CHECK ROTATIONAL FORCE OFTEN WHILE TORQUEING, AS THE ROTATIONAL FORCE WILL GIVE YOU A BETTER INDICATION OF PINION BEARING PRE-LOAD THAN THE PINION NUT TORQUE. TORQUING CLOSE TO, BUT NOT EXACTLY TO, THE SPECIFIED TORQUE MAY BE REQUIRED IF ROTATIONAL FORCE LIMIT HAS BEEN REACHED.

16. REMOVE AND REPLACE EXTRA SMALLER PINION BEARING FROM MAIN CASE. RETAINING RING CAN BE PRIED OUT AND USUALLY REUSED IF NOT DESTROYED. ENSURE CASING AROUND THIS BEARING IS NOT CRACKED (SEE SECOND PICTURE, LEFT SIDE). IT IS A COMMON PROBLEM, ESPECIALLY AFTER HARD USE. IF IT IS CRACKED, YOU MAY WANT TO CONSIDER UPGRADING TO A NODULAR CASE AND/OR A PINION HOUSING THAT ACCEPTS LARGER BEARINGS.

17. USING CALIPER, MEASURE THICKNESS OF METAL SHIM THAT WAS REMOVED WHEN PINION ASSEMBLY WAS REMOVED FROM MAIN CASE. INSTALL PINION ASSEMBLY. ENSURING THAT O-RING IS NOT DAMAGED AND THAT METAL SHIM IS ALIGNED PROPERLY (SEE PICTURES AFTER STEP 14). IF YOU ARE INSTALLING NEW PINION (GEARSET), YOU MAY WANT TO CHECK AND SEE IS END OF OLD AND NEW PINIONS HAVE MARKS LIKE +1 OR -2. IF THEY BOTH HAVE THIS MARKING, THIS WILL ALLOW YOU TO ADD OR SUBTRACT PINION SHIMS IN THOUSANDS (.001) OF AN INCH. IF OLD PINION WAS +2 AND NEW PINION IS -1, YOU WILL NEED TO SUBTRACT .003 INCHES FROM THE ORIGINAL SHIM. THIS IS OPPOSITE WHAT YOU WOULD DO ON MOST DIFFERENTIALS, AS PINION SHIMS ON A FORD 9 INCH CHANGE PINION DEPTH IN THE OPPOSITE DIRECTION COMPARED TO MOST DIFFERENTIALS. THIS WILL GIVE YOU A GOOD STARTING POINT FOR PINION DEPTH

18. IF DIFFERENTIAL IS TO BE REPLACED/REBUILT OR NEW GEARSET IS TO BE INSTALLED, REMOVE RING GEAR BOLTS, TAP RING GEAR OFF WITH PLASTIC HAMMER. USE AXLE SHAFT INSERTED INTO ONE END OF DIFFERENTIAL TO AID IN REMOVING RING GEAR BOLTS. IF RING /PINION AND DIFFERENTIAL ARE TO BE RE-USED, MARK RING GEAR SO IT CAN BE REPLACED IN THE EXACT SPOT IT WAS TAKEN OFF FROM.

19. REBUILD/REPLACE DIFFERENTIAL. REPLACE BEARINGS IF DESIRED BY PRESSING OFF AND BACK ON. REPLACE RACES IF BEARINGS ARE REPLACED. ATTACH RING GEAR AND TIGHTEN BOLTS IN A CRISS-CROSS PATTERN. TIGHTEN IN INTERVALS TO ASSURE CORRECT RING GEAR SEATING. FINAL TORQUE SHOULD BE 65-85 FT-LBS. TIGHTEN BY REVERSING PROCEDURE FOR REMOVAL SHOWN ABOVE.

20. MOVE MAIN CASE WITH PINION ATTACHED ON IT SIDE. ENSURE PINION ROTATES FREELY. GET BEARING CAPS READY AND SET UP MAIN CASE ON THE BLOCKS METIONED IN PART 8.

21. INSTALL RING/GEAR AND DIFF ASSY, INSTALL BEARING CAPS. LEAVE BEARING CAP BOLTS LOOSE FOR NOW.

22. SCREW IN SIDE ADJUSTERS INTO SIDE OF MAIN CASE/BEARING CAPS. IF IT GETS HARD TO TURN THEM YOU CAN USE TWO PHILLIPS SCREWDRIVERS TO ROTATE THEM.

23. SET UP DIAL INDICATOR AS DESCRIBED IN PART 9. ROTATE ADJUSTER, OPPOSITE RING GEAR TEETH, UNTIL RING GEAR IS TIGHT AGAINST PINION GEAR. ROTATE OPPOSITE ADJUSTER UNTIL IT IS TIGHT. LOOSEN AND TIGHTEN EACH ADJUSTER UNTIL THEY ARE BOTH TIGHT, BUT YOU HAVE .008 INCHES OF BACKLASH AS DESCRIBED IN PART 9. SNUG UP BEARING CAP BOLTS.

24. PAINT ALL RING GEAR TEETH, BOTH SIDES, WITH GEAR MARKING COMPOUND (USUALLY A WHITE TYPE OF GREASE). PUT FORCE ON RING GEAR IN EITHER DIRECTION (SMALL RUBBER PAD PRESSED AGAINST RING GEAR TEETH WORKS WELL FOR THIS). SPIN PINION/FLANGE BACK AND FORTH, 10 OR 20 TIMES, ENSURING 5 OR 6 RING GEAR TEETH MESH WITH PINION GEAR TEETH. RELEASE FORCE ON RING GEAR AND ROTATE IT TO A POINT WHERE PREVIOUSLY MESHED TEETH (PATTERN IN GREASE) CAN BE SEEN. PATTERN SHOULD LOOK LIKE CORRECT MESH PATTERN IN PICTURE AFTER PART 10.

25. REPEAT PROCEDURE, FORCING RING GEAR IN OPPOSITE DIRECTION. CHECK PATTERN AGAIN. BOTH PATTERNS SHOULD BE IN CENTER OF TOOTH AND NOT RUNNING OFF THE EDGE OF ANY TEETH. PATTERN CAN BE CHECKED AT VARIOUS LOCATIONS ON RING GEAR TO ENSURE PATTERNS ARE THE SAME OVER ENTIRE RING GEAR. DOING THIS WILL ALSO ENSURE RING GEAR IS SEATED CORRECTLY ON DIFFERENTIAL AND RUNOUT ON RING GEAR IS ACCEPTABLE. IF RING GEAR/PINION GEARS WERE REUSED, SKIP PART 26.

26. IF PATTERN IS NOT CORRECT, IN BOTH DIRECTIONS, PINION ASSEMBLY MUST BE REMOVED AND A DIFFERENT SHIM MUST BE INSTALLED. YOU SHOULD ONLY ADD/SUBTRACT .002 INCHES OF SHIM AT THE MOST WHEN CHANGING THE SHIM(S) THICKNESS THE FIRST TIME. THICKER SHIMS CAN BE ADDED THE SECOND TIME, DEPENDING UPON HOW MUCH THE PATTERN CHANGES. IT TAKES SOME PRACTICE TO DETERMINE HOW MUCH SHIM TO ADD/SUBTRACT. PINION ASSEMBLY MUST BE THEN RE-INSTALLED AND SIDE ADJUSTERS SET UP AGAIN SO THAT BACKLASH IS ONCE AGAIN .008.

27. REPEAT STEPS 24-26 UNTIL PATTERN IS CORRECT. THIS IS THE HARDEST PART OF REBUILDING A REAR END ASSEMBLY. IT MAY TAKE MANY TRYS OR EVEN DAYS TO GET IT RIGHT. BE PATIENT IF IT IS YOUR FIRST TIME. SKIP TO PART 28.

28. IF PATTERN IS NOT CORRECT, ADJUST SIDE ADJUSTERS AND CONSEQUENTLY BACKLASH UNTIL PATTERN IS CORRECT. PINION SHIM THICKNESS SHOULD NOT HAVE TO BE CHANGED, AS RING/PINION GEAR RELATIONSHIP HAS NOT BEEN CHANGED. IF YOU CAN NOT GET PATTERN CORRECT, YOU WILL NEED TO REPEAT SECTIONS 24-26 UNTIL PATTERN IS CORRECT.

29. AFTER PATTERN AND BACKLASH HAVE BEEN DETERMINED TO BE CORRECT, YOU NEED TO ENSURE THAT SIDE ADJUSTERS ARE SNUGGED UP BY HAND ONLY ON BOTH SIDES. SIDE ADJUSTERS NEED TO THEN BE ADJUSTED TIGHTER, TO CREATE A PRELOAD ON DIFFERENTIAL BEARINGS. EACH SIDE ADJUSTER NEEDS TO BE MOVED IN .004 TO .006 INCHES FOR NEW BEARINGS OR .003-.004 FOR USED BEARINGS. THERE ARE HOLES LOCATED ON EACH SIDE ADJUSTER. ROTATING THE ADJUSTER TO MOVE FROM ONE HOLE TO THE NEXT WILL GIVE YOU .005 INCHES OF PRELOAD FOR EACH HOLE TO HOLE DISTANCE. YOU WILL HAVE TO EYE THIS AND MOVE THE ADJUSTERS ACCORDINGLY. IF YOU HAVE ACCESS TO A CASE SPREADER, YOU CAN SPREAD THE MAIN CASE THE CORRECT AMOUNT, AND THEN JUST SNUG UP THE ADJUSTERS BY HAND.

30. APPLY LOKTITE TO MAIN BEARING CAP BOLTS AND TIGHTEN TO 75-85 FT-LBS. INSTALL SIDE ADJUSTER RETAINERS, APPLY LOKTITE TO SMALL BOLTS AND TIGHTEN.

31. ENSURE RING AND PINION MESH SMOOTHLY AROUND ENTIRE RING GEAR SURFACE. REPLACE 3RD MEMBER IN AXLE HOUSING. I GAVE UP ON GASKETS, AS THEY TENDED TO LEAK FOR ME. I USE ONLY GASKETMAKER BETWEEN THE HOUSING AND 3RD MEMBER. INSTALL BRASS WASHERS. THEY MAY HAVE TO BE BENT BACK INTO SHAPE IF THEY WERE DEFORMED UPON REMOVAL. TORQUE 3RD MEMBER NUTS IN A CRISS-CROSS PATTERN TO 30-40 FT-LBS. INSTALL AXLES AND TORQUE 4 NUTS TO 50-75 FT-LBS. INSTALL BRAKE DRUMS, WHEELS AND ROAD TEST.

YA JUST REBUILT YA FIRST REAR!!! :-)

PS; IF IT BLOWS UP IN 20 MILES, JUST GET IT OVER WITH AND GET A DANA 60. IT'S A MUCH BETTER REAR ANYWAY. HEEHEE.

Quelle: http://www.ford-trucks.com/articles/9inch/index.html